Top Benefits of SBS Modified Asphalt

By MBTechnology.

How SBS improves asphalt as a roofing material.

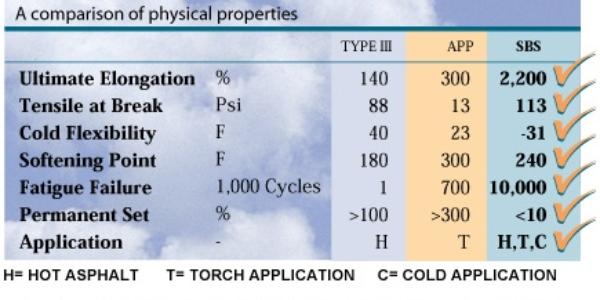

While asphalt roofing remains a popular waterproofing material, it comes with significant downsides. The poor aging of the material, its little resistance to fatigue and its tendency to become brittle in cold weather and fluid in hotter temperatures hardily make asphalt an ideal roofing material. The solution to the downfalls of asphalt is in SBS modified asphalt.

Styrene-Butadiene-Styrene (SBS) is a type of synthetic rubber derived from styrene and butadiene. The elastic compounds of SBS are flexible and durable, improving the weak points of asphalt as a material.

SBS rubber is flexible and has the memory to return to its original form. The addition of SBS rubber to asphalt increases the flow characteristics and improves the low-temperature flexibility and fatigue resistance of roofing asphalt. The end product is a high-performance, 2-3 ply system. Some of the advantages of the system are:

Flexibility of application method

-

Heat welded: Ideal for areas where it is impractical to use hot asphalt (e.g., hospital, schools and high-rises).

-

Cold adhesive: Minimizes the presence of any odor during the project.

-

Hot asphalt: The most economical way to apply the membrane. Better suited for new construction and larger projects.

-

Self-adhesive: Ideal for projects where above installations are not feasible.

Ease of maintenance

Unlike single-ply membranes which need to be maintained by an “authorized contractor”, SBS Modified Asphalt membranes can easily be maintained by in-house maintenance staff.

Compared to single-ply membranes, which are applied in one layer of 40-80 mils thickness, SBS modified systems are applied in 2-3 ply applications, ranging from 220 mils to 300 mils thickness. The redundancy of multiple layers reduces the chance of workmanship error and increases the ability to withstand traffic and numerous penetrations within the roofing system.

SBS Modified Asphalt Roofing Systems utilize a minimum of two layers (smooth and granulated) in constructing the flashing. Unlike single-ply roofs, which only have one layer of 40-80 mils thick in their flashing, the superior construction gives the flashing more ability to withstand movement and temperature fluctuation.

SBS modified bitumen performs even after 10,000,000 cycles of fatigue testing, while blown bitumen and APP modified bitumen fail in the early stages.

Learn more about MBTechnology in their RoofersCoffeeShop® Directory or visit mbtechnology.com.

Original article source: MBTechnology

Comments

Leave a Reply

Have an account? Login to leave a comment!

Sign In