Common Problems with Rollforming Machines - Part 3

By New Tech Machinery.

Everything you need to know to troubleshoot shear misalignment.

In part one, we explained how oil canning occurs and ways to prevent it from happening. In part two we shared about panel curvature and the necessary adjustments to make when this happens. Part three focuses on shear misalignment and will outline the most common ways to fix this problem.

Problem #3 - Shear Misalignment

What is Shear Misalignment?

At NTM, our roof panel rollformers are post-cut machines, which means a shear is used to cut the panels after it’s rollformed and before it exits the machine. When there is a shear alignment issue, the shear is not accurately cutting panels, which may mean that the entry/exit shear dies are misaligned or the shear blades are not appropriately positioned according to the profile type.

To spot shear alignment issues, you may see:

-

The shear is cutting the metal in a jagged or uneven manner

-

A sheared panel is hitting or getting snagged on the exit die

-

A worn out center mandrel

-

A broken shear die

Why Does Shear Misalignment Occur?

The shear, which is electrically activated and hydraulically driven in NTM’s SSQ II Machine, is not “one size fits all” for every metal roof panel profile. For example, the entry and exit shear dies might be in alignment for rollforming the SS450 profile but are completely out of alignment for the SSQ275 profile. In other words, it’s not always that the shear is broken or something happened to the part, but rather that it just needs to be adjusted to fit the current profile.

Additionally, improper cutting might be due to inadequate maintenance performed on the shear.

How to Fix Shear Alignment

There is more than one way to fix the problems you might be experiencing with the shear. We’re going to outline a few of the most common fixes. If you are making the following adjustments and the issue is not resolved, please contact NTM’s service department so they can walk you through further steps to remedy the problem.

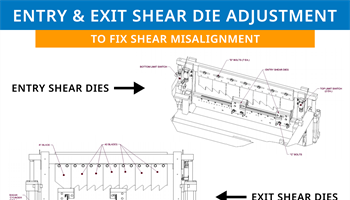

Adjusting the Entry and Exit Shear Dies

The entry and exit shear dies are specific to each roller set and may need to be changed when changing profiles. The dies must be adjusted to the proper distance from the vertical legs of the panel. The outside vertical leg of the male and female entry dies should be approximately 1/32” away from the outside of the vertical legs of the panel. The exit dies should be positioned slightly to the outside of the male and female entry dies so that after a cut is made, the panel does not get hung up on the exit dies.

Entry and Exit Shear Die Adjustments

-

Run material through the machine until it is about six inches away from the shear, then shut off the machine and disconnect the power.

-

Sight down the legs of the panel to find the approximate location to install the entry shear dies. Hold them in place with the “C” bolts but do not tighten them yet.

-

Start up the machine and carefully jog the material forward while looking through the dies. If it seems like the panel will hit the dies, shut off the machine and disconnect the power. Then, further adjust the dies as necessary until the panel goes through cleanly.

-

Continue jogging the panel forward until it is about an inch or two past the shear dies, then shut off the machine and disconnect power.

-

Adjust the entry shear dies until they are about 1/32” away from the outside of the vertical leg of the panel. Each profile will look different, so make sure to reference your manual to see how it is shown. Tighten the “C” bolts.

-

If the entry shear dies has a mandrel, it should be positioned as shown in the figure for your panel. If necessary, loosen the “E” bolts and adjust the mandrels. Retighten the “E” bolts.

-

Install the exit shear dies and adjust them so they are about 1/32” to the outboard of the entry shear dies, as shown in the figure for your panel. Tighten the “C” bolts.

-

Adjust the mandrel on the exit shear die as needed, if it has one.

Blade Adjustments

-

To cut properly, the top blades need to be positioned so that one of the #2 blade tips is just to the inside of the male leg. Also, the top of the #1 blade is positioned to the inside of the female leg. The rake or angle of the blades should cut in a scissor action outward against the legs. If necessary, loosen the seven “D” bolts and move the top blades left or right to get them in the correct position. Retighten the bolts.

-

Start the machine and shear off a panel about 12 inches long, then job the material forward a few inches. Make sure the panel is not scraping on the shear dies and inspect the quality of the cut on both sides. If any corrections need to be made, shut off the machine and disconnect the power, then adjust the shear dies.

Maintaining the Shear

Clean and lubricate the top blades, bottom dies, and male/female dies at least once a day (or approximately every 30 cuts) during regular use, or whenever cutting surfaces look dry. Proper lubrication is essential to clean cuts, rust prevention, and longevity of the shear.

We recommend Super Lube Multi-Purpose Synthetic Dri Film Aerosol Lubricant with Syncolon as a shear lubricant (it’s also available to purchase through New Tech Machinery).

(Note: The shear is extremely dangerous and can cause serious bodily injury or death. For this reason, the machine is provided with a guard to prevent the operator from reaching into the shear. It is crucial that the guard remains in place at all times when the machine is in operation. The guard should only be removed for maintenance and adjustment of the shear when the machine is unplugged/unpowered.)

Make sure to check back next week for part 4 covering panel markings

Learn more about New Tech Machinery.

Recommended For You

Nearmap to Provide Free High-Resolution Aerial Imagery to Health Officials and Government Agencies for COVID-19 Relief Efforts

Read More ...

Gypsum Has You Covered: USG Securock® Brand Gypsum-Fiber Roof Board

Read More ...

Cool Roofing Solutions: How Metalflex SBS Can Increase Energy Efficiency

Read More ...

Comments

Leave a Reply

Have an account? Login to leave a comment!

Sign In